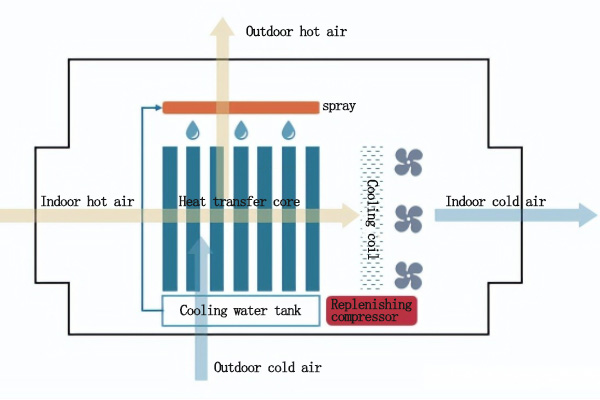

Indirect evaporative cooling technology (IEC) is a unique cooling method for evaporative cooling. When the technology is applied to the data center, the secondary air is mostly the outdoor low temperature fresh air, and the primary air is mostly the heat return air in the machine room. The driving force is the sensible heat difference between the two, and the heat transfer from the server to the outdoor side air through the heat conduction of the heat exchanger tube wall, so as to achieve the purpose of cooling the data center return air.

Evaporative cooling system can also use water evaporation, through the spray to absorb the heat in the outdoor secondary air, heat exchanger from dry bulb temperature to wet bulb temperature, to cool the primary air in the machine room, enhance the refrigeration effect.

Indirect evaporative cooling system

The indirect evaporative cooling system is composed of spray device, heat exchange core, indoor fan, outdoor fan, mechanical refrigeration supplement device, control system, etc. The application of the unit only needs to install air pipes, water pipes and power distribution in the data center, and it can be put into use. The unit has three operation modes: dry mode, wet mode and mixed mode.

(1) Dry mode, natural cooling

In the case of low outdoor temperature in winter, the outdoor air temperature is low enough to cool the server room in the heat exchanger for return air. After passing through the heat exchanger, the heat-absorbing outdoor air is discharged to the outside by the fan wall. The cooled air is returned to the server room through the side fan wall.

(2) Wet mode, evaporative cooling

In the case of low outdoor temperature in spring and autumn, because the outdoor air temperature is not low enough, it is necessary to open the water pump for adiabatic evaporation refrigeration through high pressure micro mist spray to supplement the cooling capacity.

(3) Mixing mode, mechanical cooling

In the case of high outdoor temperature in summer, natural cooling can not meet the cooling demand, circulating water to take away part of the heat, not enough to open the frequency conversion compression refrigeration system to supplement the cooling capacity.

The switching of the above three operating modes depends on the dry bulb temperature and wet bulb temperature of outdoor air, and the boundary of outdoor dry and wet bulb temperature is determined by the temperature of air supply and return in the data center room and the heat transfer efficiency of indirect evaporative cooling heat exchange core.

Application of indirect evaporative cooling technology

Indirect evaporative cooling is through the evaporation of water to absorb heat to refrigeration, only when the air used has a large dry and wet bulb temperature difference, it may have a good cooling effect. Therefore, indirect evaporative cooling technology is very suitable for Xinjiang, Gansu and other summer outdoor dry and wet bulb temperature difference area.

Compared with the general conventional mechanical refrigeration, it can save 80% ~ 90% energy in hot and dry areas, 20% ~ 25% energy in hot and humid areas, and 40% energy in medium humidity areas, thus greatly reducing the energy consumption of air conditioning refrigeration. According to the conditions, requirements, geographical and meteorological parameters of each region, it also has a great prospect of application.

In low temperature (outdoor dry bulb temperature < 15℃), indirect evaporative cooling can basically keep running in dry mode. The natural cooling source can be fully utilized to extend the free cooling source time and reduce the energy consumption of the data center cooling system.

The customized channel sealing assembly + the whole cabinet and the floor and the top hot interlayer form a completely closed and isolated air flow organization structure. The cold air is sent under the floor through the air bin on both sides, heated by the server, mixed evenly through the return air outlet on the roof, and then inhaled into the indirect evaporative cooling unit at the top for recycling. The whole process can greatly reduce the loss of cold source.

Post time: Jun-14-2023