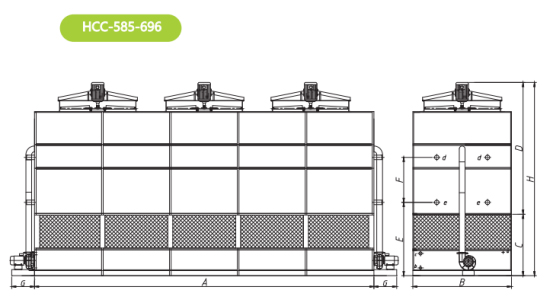

Countercurrent Closed CoolingTower

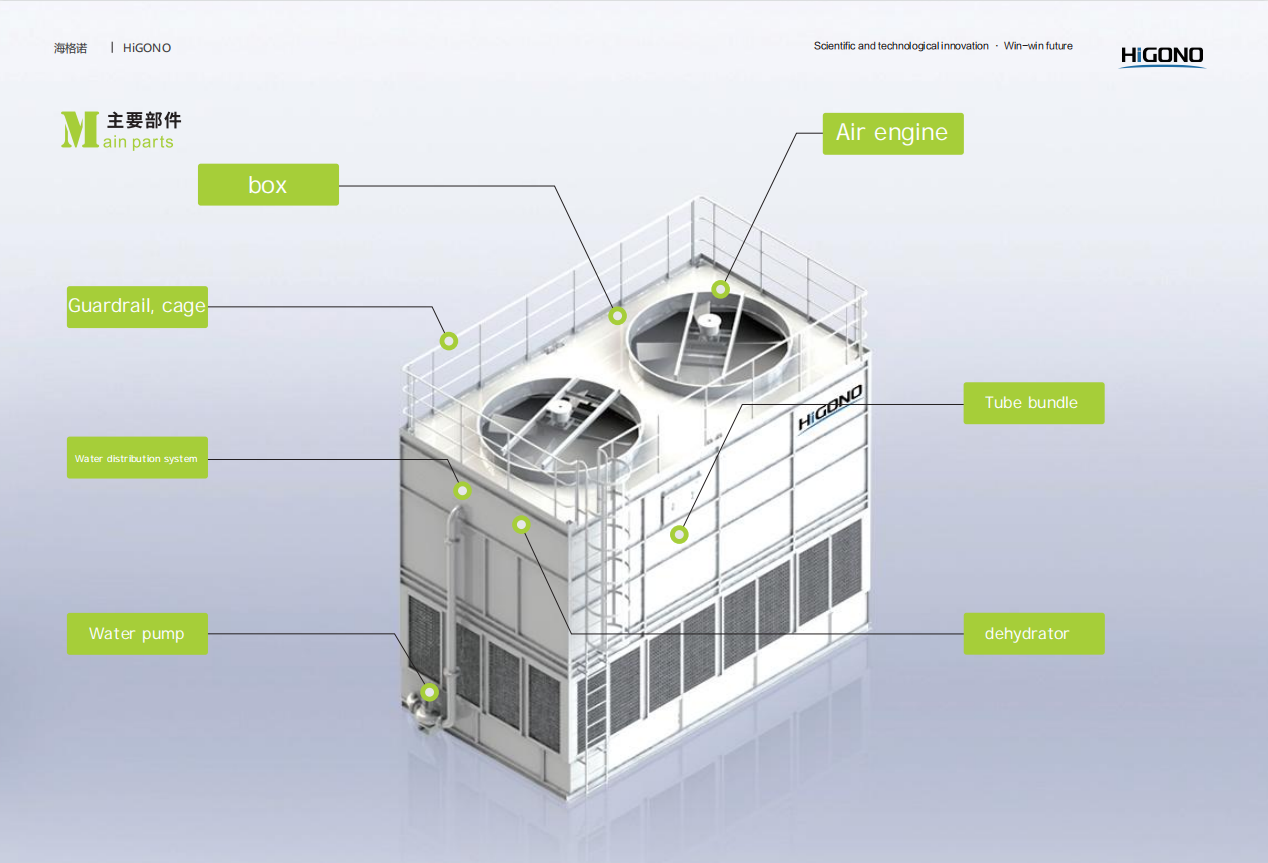

Main parts

Box

Aluminum plated zinc steel plate; It has the advantages of strong thermal resistance and excellent heat resistance.

Other options: galvanized plate G235, stainless steel 304, 316L, etc.; Special equipment size customization.

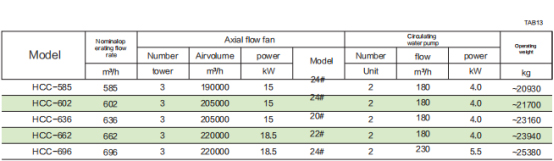

Air blower

Adopt direct axial fan, IP55 outdoor waterproof motor.

It has the advantages of low noise, high efficiency, few friction parts, no transmission loss and low fault.

Other options :IP56/IP66 protection grade; Explosion- proof, variable speed motor; Aluminum alloy, high strength fiber blade; Optional motor brand.

Water distribut system

The use of removable, large flow anti-blocking blue nozzle, to ensure that the water is continuously and evenly covered on the surface of the coil, improve the heat transfer effect.

Dehydrator

Corrosion resistant VPC material is used to effectively remove water droplets in saturated wet air, so that the water floating rate is less than 0.001%;

Detachable design is convenient for later cleaning and maintenance of the equipment.

Water pump

It adopts low-noise, fully enclosed, anti-splash and dustproof outdoor motor, equipped with stainless steel impeller and high quality mechanical seal.

It has the advantages of low energy consumption, excellent performance and long service life.

Other optional :IP56/66 protection grade; Explosion-proof motor; Optional motor brand.

PVCpacking

Specially designed PVC honeycomb packing has the advantages of good flame retardancy, small wind

resistance coefficient, anti-aging and so on.

Other options: CPVC, PP filler.

Tube bundle

The pipe adopts round steel pipe, and the tube bundle is tested for air tightness three times.

Integral hot-dip chain treatment improves corrosion resistance and prolonging service life.

Other optional: stainless steel 304, 316L, etc.

Special coil thickness, test pressure customization.

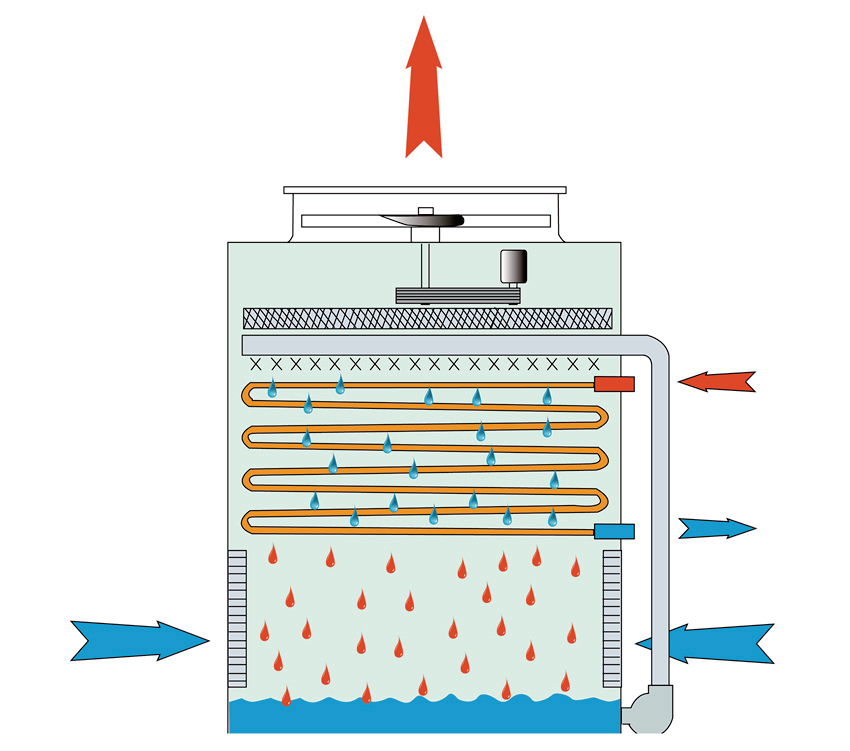

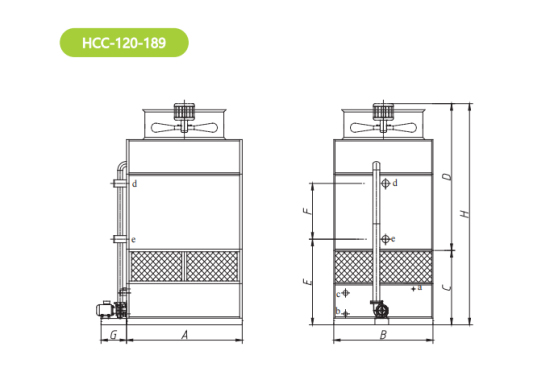

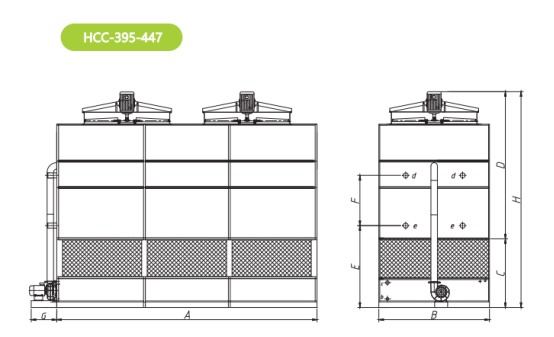

Peration principle

With water and air as cooling medium, countercurrent heat exchange is adopted. The hightemperature liquid enters from the upper header of the coil, and the cooled liquid flows out from the lower header of the coil using the evaporation of circulating cooling water to carry away the heat released by the high-temperature fluid during the cooling process. The axial fan is placed on the top of the equipment, and the inlet is located around the lower box of the equipment, and the fresh air will enter the heat exchange with the water from the lower side around, and the evaporated water steam will be discharged into the atmosphere. The cooling water is sent to the spray pipe above the cooling coil by the pump, and is evenly sprayed on the outer surface of the cooling coil to form a thin layer of water film. Part of the water vaporized into steam due to endothermic heat is sucked away and discharged into the atmosphere by the axial flow fan, thus achieving the transfer of heat.

Area cooperation

Food processing

Polysilicion

Cold-china logistics

Industrial refrigeration

Cold storage

Fruit juice and dairy

Data center

Electric power generation

Chemical industry

Pharmaceutical

Competive adcantage

Modular design, easy to install and transport equipment on site.

Provide customized design services to meet the application requirements of different projects.

Equipped with the first evaporative cooling, closed tower test center in China, the data is real and reliable to ensure product performance.

Stainless steel and carbon steel materials are managed and processed in different areas to avoid rust infection during processing.

Independent raw material leveling, to ensure that the material is real and reliable, eliminate shoddy, to ensure product quality .

The plate is cut by laser, which is precise and beautiful, and reduces the error caused by manual operation.

Accessories are sandblasted to keep the inside of the equipment clean.

Three-dimensional warehouse, product parts classification is clear, reduce delivery errors.

Apply big data system to track and supervise production progress and refine production management.