Screw Condensing Unit

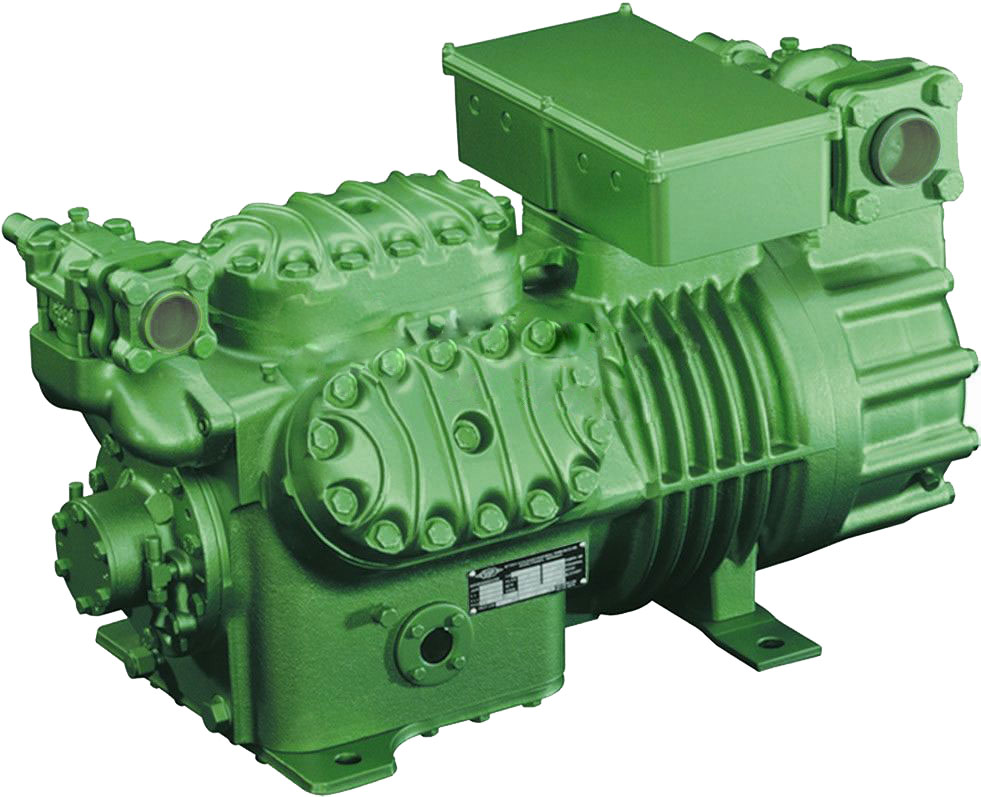

Main parts

Leading manufacturing process

High quality steel, large axle diameter, high wear resistance, high class profile, high quality materials, precision processing equipment and fine assembly process, the best fit gap, high energy efficiency compressor precision.

Optimized fuselage design

Integrated design concept, reduce parts, compact structure, safe and reliable

Advanced and reliable screw

High quality steel, large axle diameter, high wear resistance, high precision.

High quality casting material

Integrated structure, built-in oil circuit, precision manufacturing, smooth circulation, low noise, low vibration, high efficiency.

Double slide valve

Variable compressor content ratio eliminates "over-compression" or "under-compression" to ensure low noise and high efficiency.

Efficient multistage oil content

Quiet design built-in oil, full liquid and falling film units are ideal.

Mprove efficiency and smooth airflow

Based on professional thermal engineering, innovative design of suction channel, so that the motor cavity uniform heat dissipation.

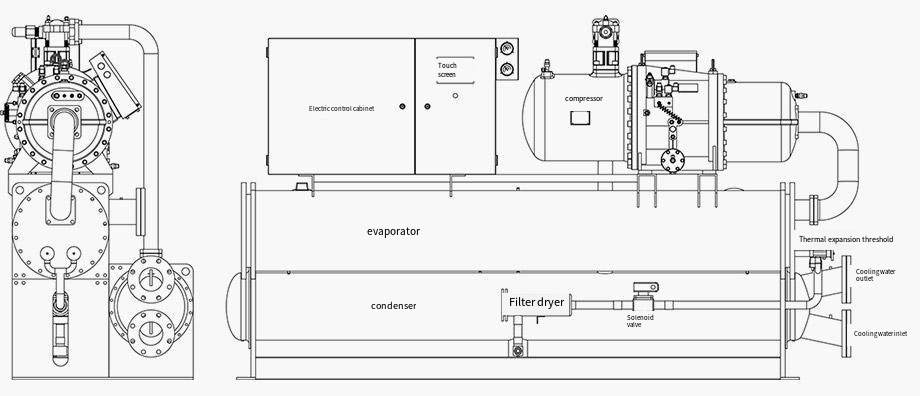

Peration principle

Screw chiller is named for its key component - compressor, which is composed of gaseous refrigerant leaving the evaporator state; After adiabatic compression by the compressor, it becomes a high temperature and high pressure state. The compressed gas refrigerant is cooled in the condenser and isobaric condensation, and becomes a liquid refrigerant after condensation, and then expands to a low pressure through the throttle valve to become a gas-liquid mixture. The low-temperature and low-pressure liquid refrigerant absorbs the heat of the cooled substance in the evaporator and becomes a gaseous refrigerant again. The gaseous refrigerant re-enters the compressor through the pipe to begin a new cycle. This is the four processes of the refrigeration cycle and the main working principle of the screw chiller. Screw chiller according to the different development of the system heat management mode can be divided into water cooling, air cooling. Water cooling uses natural cooling water tower water circulation heat dissipation problem for effective heat dissipation, and air-cooled screw chiller uses fin air environment heat dissipation.

Area cooperation

Food processing

Polysilicion

Cold-china logistics

Industrial refrigeration

Cold storage

Fruit juice and dairy

Data center

Electric power generation

Chemical industry

Pharmaceutical

Competive adcantage

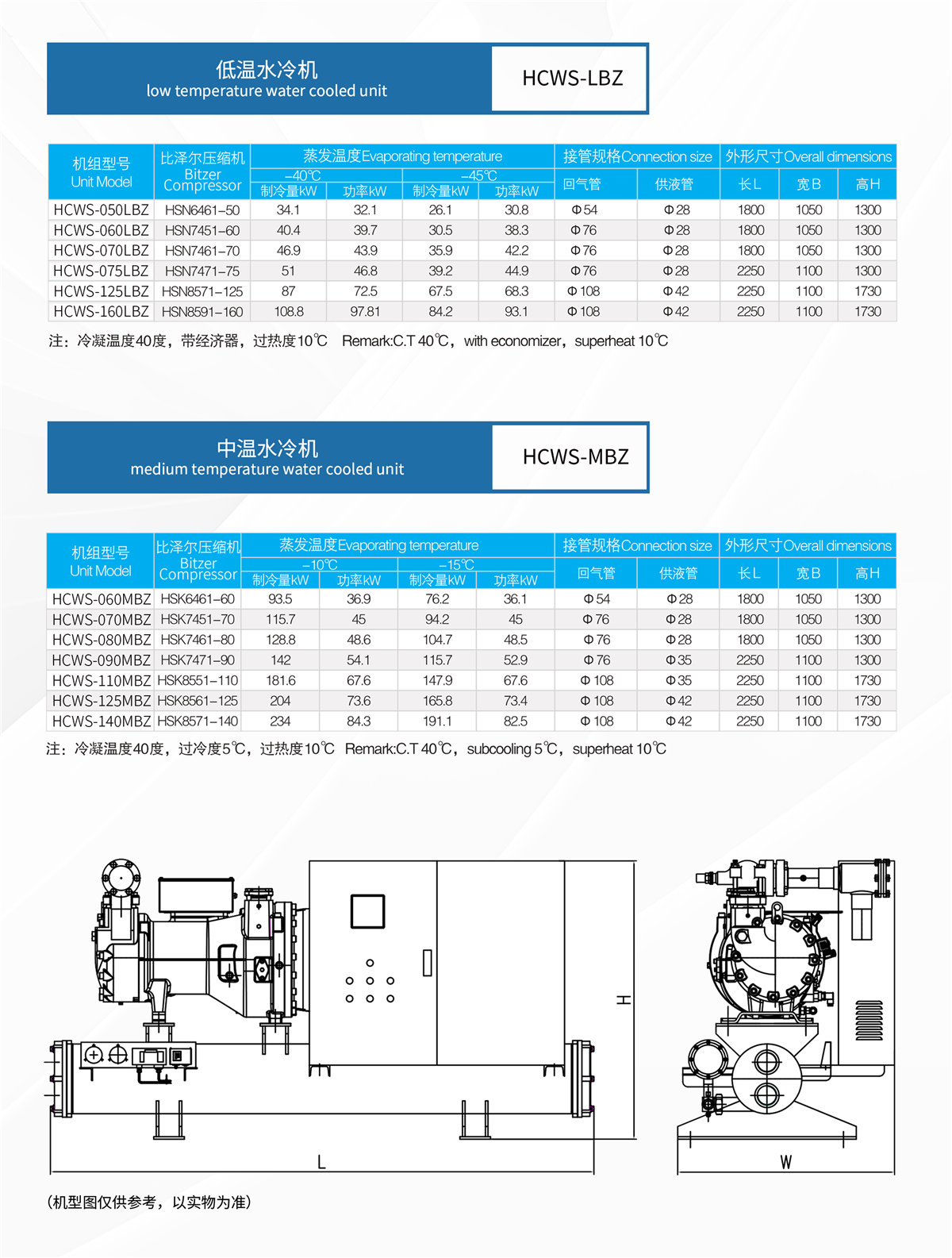

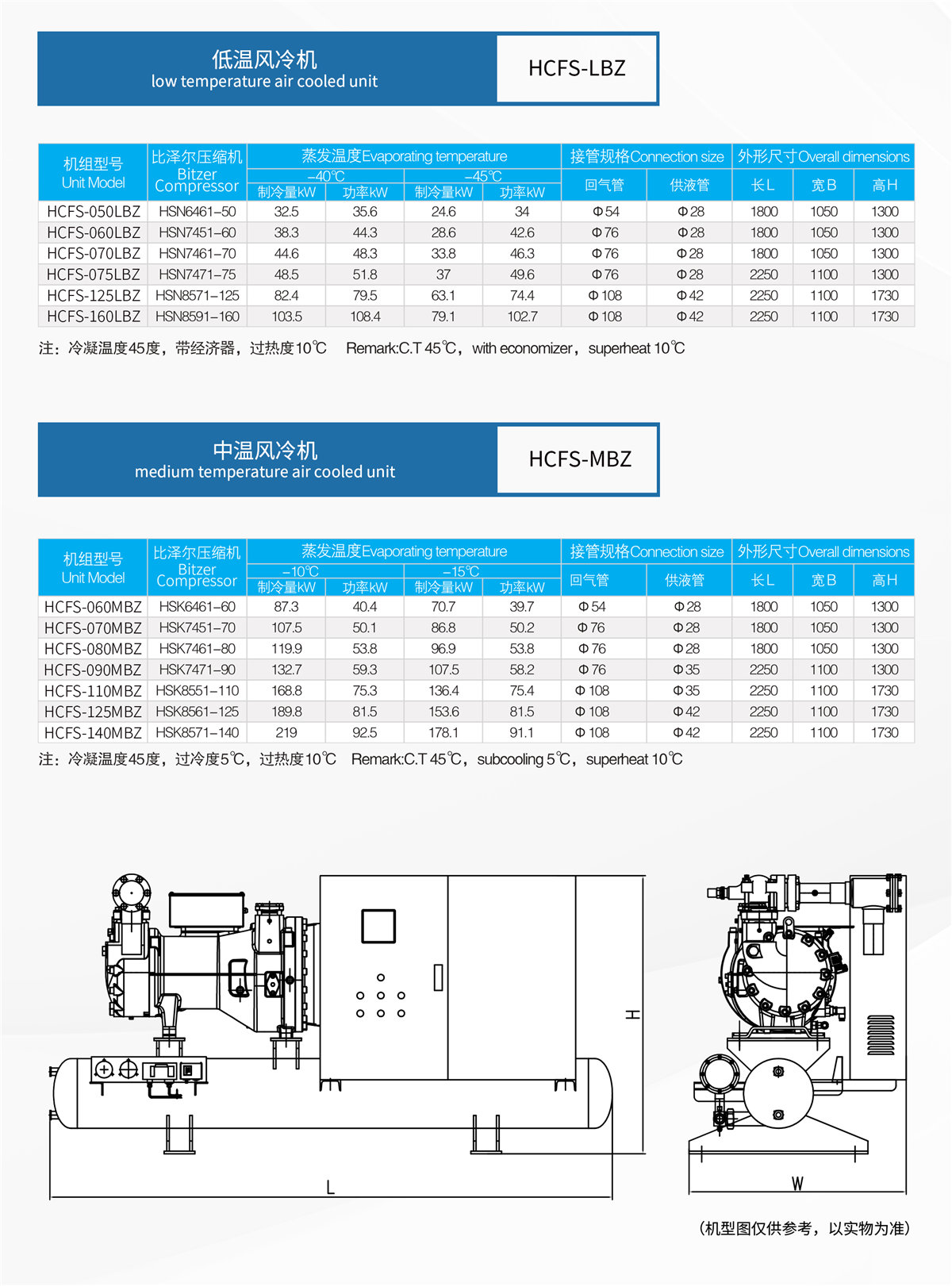

1.Adopt Bitzer compressor, with high efficiency, long life, low vibration, low noise characteristics.

2.The unit is fully equipped, the main refrigeration accessories and control components are used in the world famous brand, high reliability.

3.The unit has a variety of safety protection such as compressor reversal, overheating, overload, exhaust temperature, low oil level and compressor high and low pressure to ensure the reliability of operation.

4.With multi-level energy regulation, it can adapt to the change of different cooling loads and effectively reduce energy consumption.

5.The unit is controlled by PLC and touch screen, which can realize remote monitoring according to user requirements.