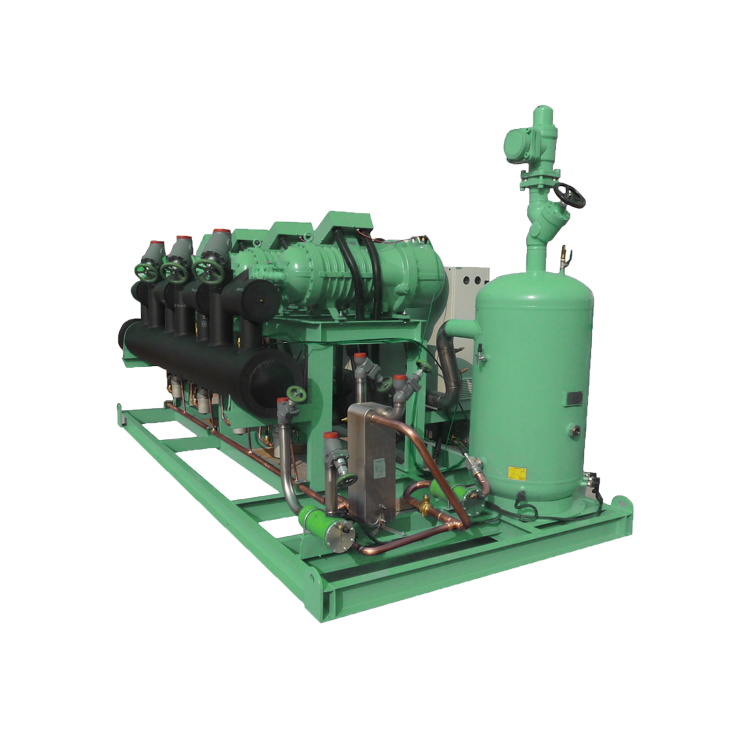

Screw Parallel Condensing Unit

Main parts

Customized according to demand

Basic configuration

-Unit frame

-Compressor (suction and exhaust stop valve, exhaust check valve)

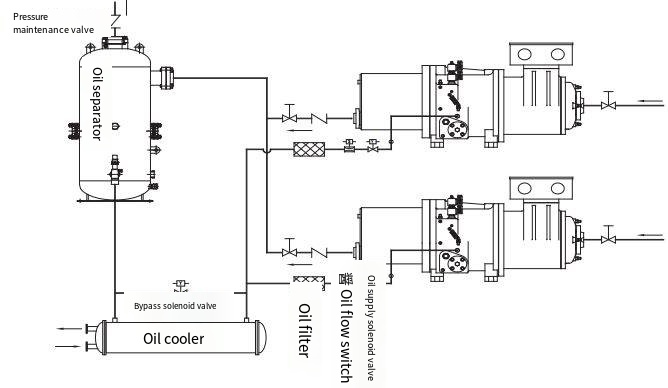

-Oil system (oil heater, external oil separator, oil flow switch, oil solenoid valve, oil mirror, oil filter, oil cooler)

-Electronic control system (PLC programming control)

-Protection device (compressor high and low pressure controller, system high and low pressure controller, oil pressure difference controller, overload, lack of phase, reverse phase, oil temperature, internal overheating protection, high pressure side pressure sensor, oil temperature control, spray control)

-High pressure gauge, low pressure gauge

-Receiver (with stop valve, liquid system filter,sight glass)

-Safety fittings (receiver safety valve,oil separator safety valve)

-Low pressure side pressure sensor

-Suction line accessories (suction filter,suction line insulation)

-Discharge line accessories (oil separator outlet check & stop valve)

Option

-Liquid level switch

-Accumulator

-Oil pump system

-Suction line accessories (suction branch stop valve, suction main line stop valve)

-Liquid line accessories (liquid branch ball valve)

-Discharge line accessories(hot gas stop valve,pressure regulator valve)

-Compressor oil

Optional equipment

-Air cooled condenser

-Water cooled condenser

-Evaporate type condenser

Peration principle

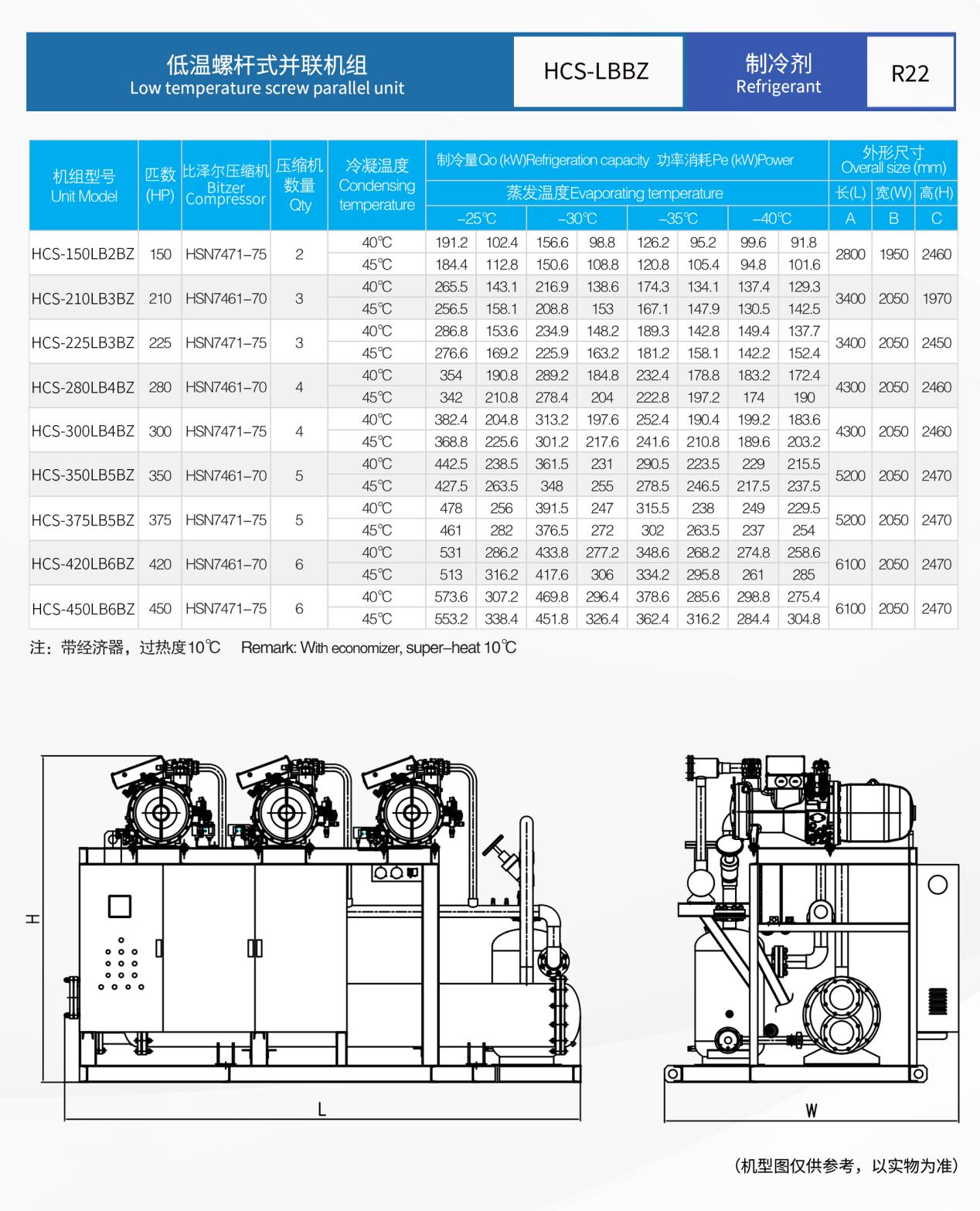

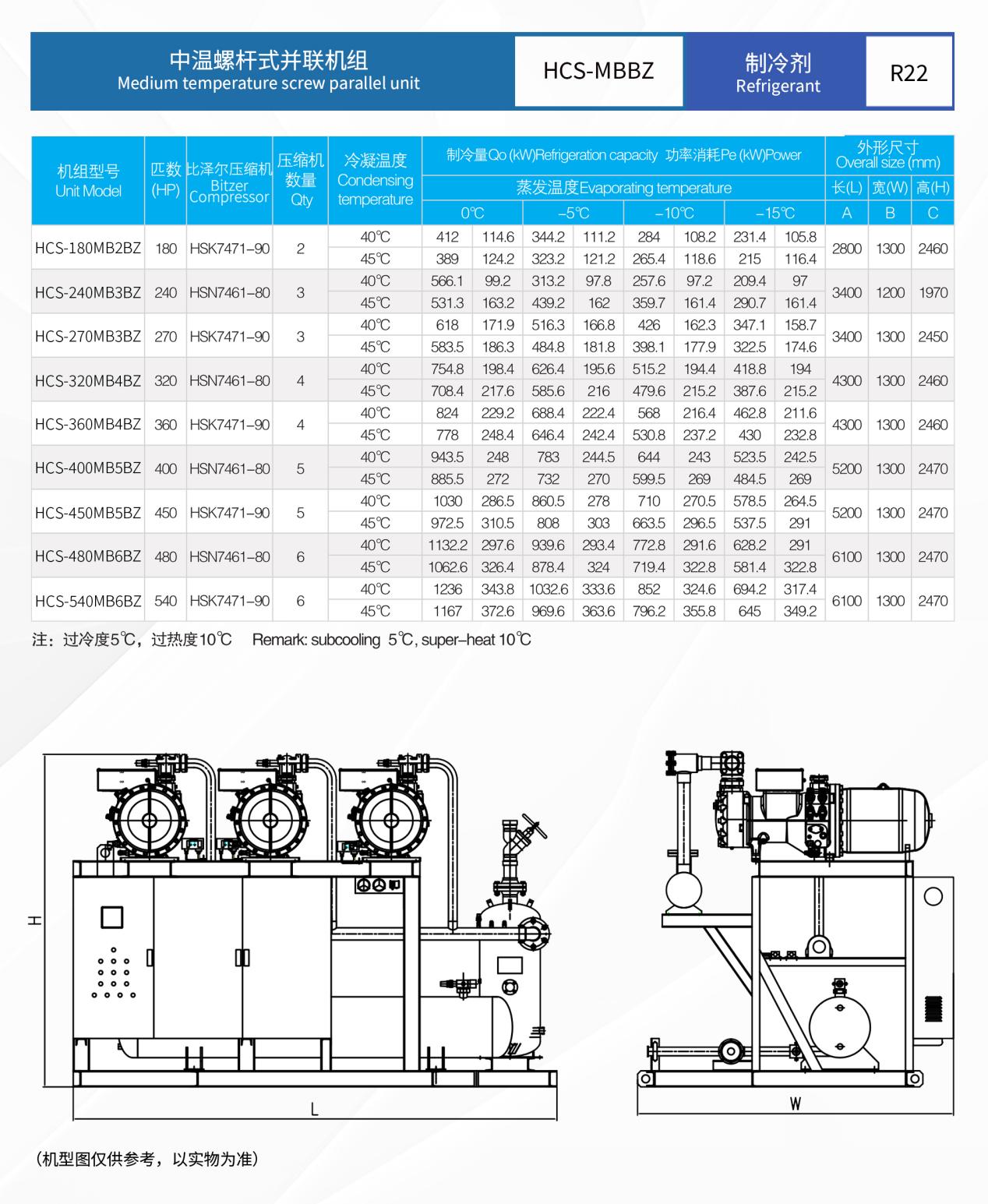

Refers to two or more compressors in parallel to share a set of refrigeration circuit composed of refrigeration units.

According to the different cooling temperature and cooling capacity, the parallel unit can be in a variety of forms.

That is, the same set of units can be composed of the same type of compressor, or can be composed of different types of compressors. Can be composed of the same type of compressor, can also be composed of different types of compressor; It can be loaded with a single evaporation temperature or several different evaporation temperatures. It can be a single-level system or a two-level system. It can be either a single cycle system or a cascading system.

Area cooperation

Food processing

Polysilicion

Cold-china logistics

Industrial refrigeration

Cold storage

Fruit juice and dairy

Data center

Electric power generation

Chemical industry

Pharmaceutical

Competive adcantage

1.Save money. Reduce one-time equipment investment;

2.Save energy. Provide cooling capacity on demand, which can save more than 20% of energy compared with a single independent unit;

3.Safe operation. Monitor the operation parameters of the unit at all times, with fault warning function to ensure safe and reliable operation;

4.Compact structure. Centralized installation of multiple heads, saving room space, short construction period;

5.Fully automated. Advanced special controller for parallel units is adopted.

6.Multiple alarm locking function. The fault code display function improves the reliability and maintainability of the unit;

7.Multistage energy regulation. The energy can be adjusted according to the change of cooling load to effectively reduce energy consumption;

8.Automatic balancing of operating rate. Greatly extend the overall service life of the unit;

9.A new type of asymmetric rotor screw compressor. With high efficiency, long life, low vibration, low noise.